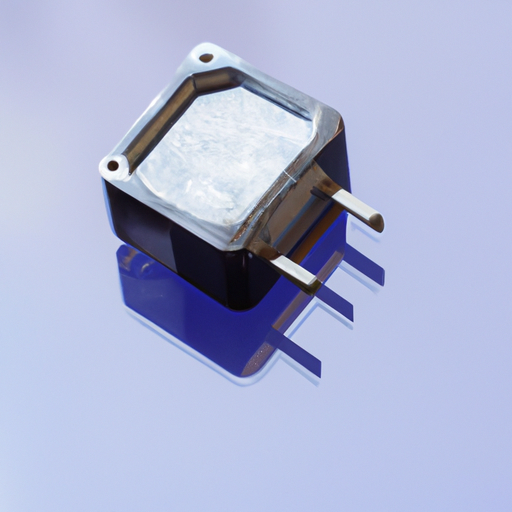

Fixed electrical sensors are an essential component in various industries, providing crucial data and information for monitoring and controlling processes. These sensors are used to detect changes in the environment, such as temperature, pressure, or humidity, and convert these changes into electrical signals that can be interpreted by a control system. To ensure the reliability and accuracy of fixed electrical sensors, there are specific product standards that must be met.

Another key product standard for fixed electrical sensors is reliability. These sensors are often used in critical applications where any failure could have serious consequences. As such, they must be able to operate consistently and reliably over long periods of time. This includes factors such as resistance to environmental conditions, resistance to electromagnetic interference, and resistance to mechanical stress.

In addition to accuracy and reliability, fixed electrical sensors must also meet standards for compatibility. This includes compatibility with the control system or data acquisition system that will be interpreting the sensor's output. The sensor must be able to provide the necessary signal output, such as voltage or current, in a format that can be easily interpreted by the system.

Furthermore, fixed electrical sensors must also meet standards for safety. This includes factors such as electrical insulation, grounding, and protection against overvoltage or overcurrent conditions. These safety standards are crucial to ensure the protection of both the sensor itself and the system it is monitoring.

In order to ensure that fixed electrical sensors meet these product standards, they are typically subject to rigorous testing and certification processes. This may include testing for accuracy, reliability, compatibility, and safety, as well as compliance with industry-specific standards and regulations.

For example, in the United States, fixed electrical sensors may be subject to testing and certification by organizations such as Underwriters Laboratories (UL) or the National Institute of Standards and Technology (NIST). These organizations provide certification that the sensor meets specific product standards and is safe for use in its intended application.

In conclusion, fixed electrical sensors are a critical component in many industries, providing essential data for monitoring and controlling processes. To ensure the reliability and accuracy of these sensors, they must meet specific product standards for accuracy, reliability, compatibility, and safety. By adhering to these standards and undergoing rigorous testing and certification processes, fixed electrical sensors can provide the necessary data and information for a wide range of applications.